Rebar Cutting Plan Optimisation for Construction Projects

Jan 02, 20261- Introduction to Rebar Cutting Optimisation

Reinforced concrete construction depends heavily on steel reinforcement bars (rebars). In most construction projects, rebar represents 15–25% of total structural cost and is one of the highest sources of material waste. Rebar cutting plan optimisation is a systematic engineering process that aims to minimise waste, reduce cost, improve productivity, and enhance sustainability by intelligently planning how required bar lengths are cut from standard stock lengths.

Traditionally, rebar cutting has been done using experience-based judgment on-site. While practical, this approach results in:

-

Excessive offcuts

-

Inconsistent waste levels

-

Poor traceability

-

Higher procurement cost

-

Increased environmental impact

Modern optimisation methods supported by mathematics, algorithms, BIM data, and AI tools allow engineers and planners to reduce waste dramatically while maintaining constructability and compliance with codes.

2 – Fundamentals of Rebar and Stock Lengths

2.1 Standard Rebar Lengths

Most rebars are supplied in standard commercial lengths:

-

12.0 m (most common)

-

9.0 m

-

6.0 m (limited availability)

Stock length selection has a direct influence on waste potential.

2.2 Rebar Weight Calculation

Rebar unit weight depends on diameter:

"Unit Weight (kg/m)" = d² / 162

Where:

-

d = bar diameter in mm

Example:

16 mm bar:

Unit Weight = 16² / 162

Unit Weight = 256 / 162

Unit Weight ≈ 1.58 kg/m

3 – The Cutting Stock Problem

Rebar optimisation is a classic cutting stock problem, where:

-

Input: required lengths and quantities

-

Constraint: fixed stock length

-

Objective: minimise waste

3.1 Waste Formula

"Waste Length" = Stock Length − Σ (Cut Lengths)

"Waste Percentage" = (Total Waste Length / Total Stock Length Used) × 100

4 – Traditional vs Optimised Cutting (Why Optimisation Matters)

Typical Industry Waste Levels

| Method | Waste % |

|---|---|

| Manual cutting | 8–15% |

| Semi-planned | 5–8% |

| Software optimisation | 1–4% |

| BIM + optimisation | 0.5–3% |

5 – Deep Construction Site Example (Quantified Savings)

5.1 Project Description

-

Project: 12-storey RC building

-

Total rebar quantity: 450 tons

-

Dominant bar diameter: 16 mm

-

Stock length: 12 m

-

Steel cost: AUD 1,200 / ton

5.2 Required Bars (Extract from BBS)

| Length (m) | Quantity |

|---|---|

| 5.6 | 18,000 |

| 4.2 | 24,000 |

| 7.8 | 6,000 |

5.3 Total Required Length

Total Length =

(18,000 × 5.6) + (24,000 × 4.2) + (6,000 × 7.8)

= 100,800 + 100,800 + 46,800

= 248,400 m

5.4 Total Weight

Total Weight =

248,400 × 1.58 / 1000

= 392.5 tons

5.5 Scenario A – Manual Cutting (10% Waste)

Total Steel Ordered =

392.5 × 1.10

= 431.8 tons

Cost =

431.8 × 1,200

= AUD 518,160

Waste Cost =

(431.8 − 392.5) × 1,200

= AUD 47,160

5.6 Scenario B – Optimised Cutting (3% Waste)

Total Steel Ordered =

392.5 × 1.03

= 404.3 tons

Cost =

404.3 × 1,200

= AUD 485,160

Waste Cost =

(404.3 − 392.5) × 1,200

= AUD 14,160

5.7 Net Savings

| Item | Value |

|---|---|

| Steel saved | 27.5 tons |

| Cost saving | AUD 33,000 |

| Waste reduction | 70% |

6 – Software Tools for Rebar Optimisation

Dedicated Optimisation

-

Cut Optimizer

-

RebarSoft

-

GoSmarter Rebar Optimisation

BIM-Integrated

-

Tekla Structures (Rebar Nesting)

-

ADDA Construct

-

Advance Workshop Rebar

-

ProRebar

7 – Using GPT for Rebar Cutting Optimisation

7.1 Why Use GPT?

GPT can:

-

Analyse BBS data

-

Propose cutting patterns

-

Compare waste scenarios

-

Explain optimisation logic

-

Assist planners without advanced software

GPT does not replace certified optimisation software, but it is extremely effective for:

-

Feasibility studies

-

Early-stage planning

-

Training engineers

-

Scenario comparison

7.2 Professional GPT Prompt for Rebar Optimisation

Use this prompt exactly as written:

You are a construction planning engineer specialised in reinforced concrete structures.

I will provide a list of required rebar lengths and quantities, stock length, and bar diameter.

Your task is to:

Generate optimised cutting patterns from the given stock length

Minimise total waste

Calculate waste percentage

Compare against a typical manual cutting scenario with 10% waste

Present results in a clear table suitable for Excel or Word

Explain all calculations step-by-step

Input data:

Stock length = 12 m

Bar diameter = 16 mm

Steel cost = AUD 1,200 / ton

Required bars:

5.6 m × 18,000

4.2 m × 24,000

7.8 m × 6,000

Assume practical site constraints and realistic cutting tolerances.

This prompt produces engineering-grade reasoning, not just numbers.

8 – Managing and Reusing Leftover Rebar (Offcuts) for Future Savings

8.1 Why Rebar Offcut Management Matters

Even with advanced rebar cutting optimisation, zero waste is unrealistic on real construction sites. However, the difference between lost waste and recoverable value depends entirely on how leftover bars (offcuts) are stored, tracked, and reused.

On most sites:

-

Offcuts are piled randomly

-

Lengths are unknown or mixed

-

Rust and damage occur

-

Engineers avoid reuse due to uncertainty

As a result, recoverable steel becomes scrap, increasing project cost and environmental impact.

With proper offcut management, 30–70% of leftover rebar can be reused in:

-

Short dowels

-

Starters

-

Stirrups

-

Secondary reinforcement

-

Temporary works

8.2 Definition of Reusable vs Scrap Rebar

8.2.1 Reusable Offcuts

A rebar offcut is considered reusable if:

-

Length ≥ minimum practical length (typically ≥ 1.0 m)

-

No excessive corrosion

-

No mechanical damage or bending

-

Same diameter and grade as required

-

Traceable to heat/grade if required by specification

8.2.2 Scrap Rebar

Scrap bars include:

-

Bars shorter than the minimum length

-

Bars with kinks or cracks

-

Heavily rusted bars

-

Mixed or unidentifiable grades

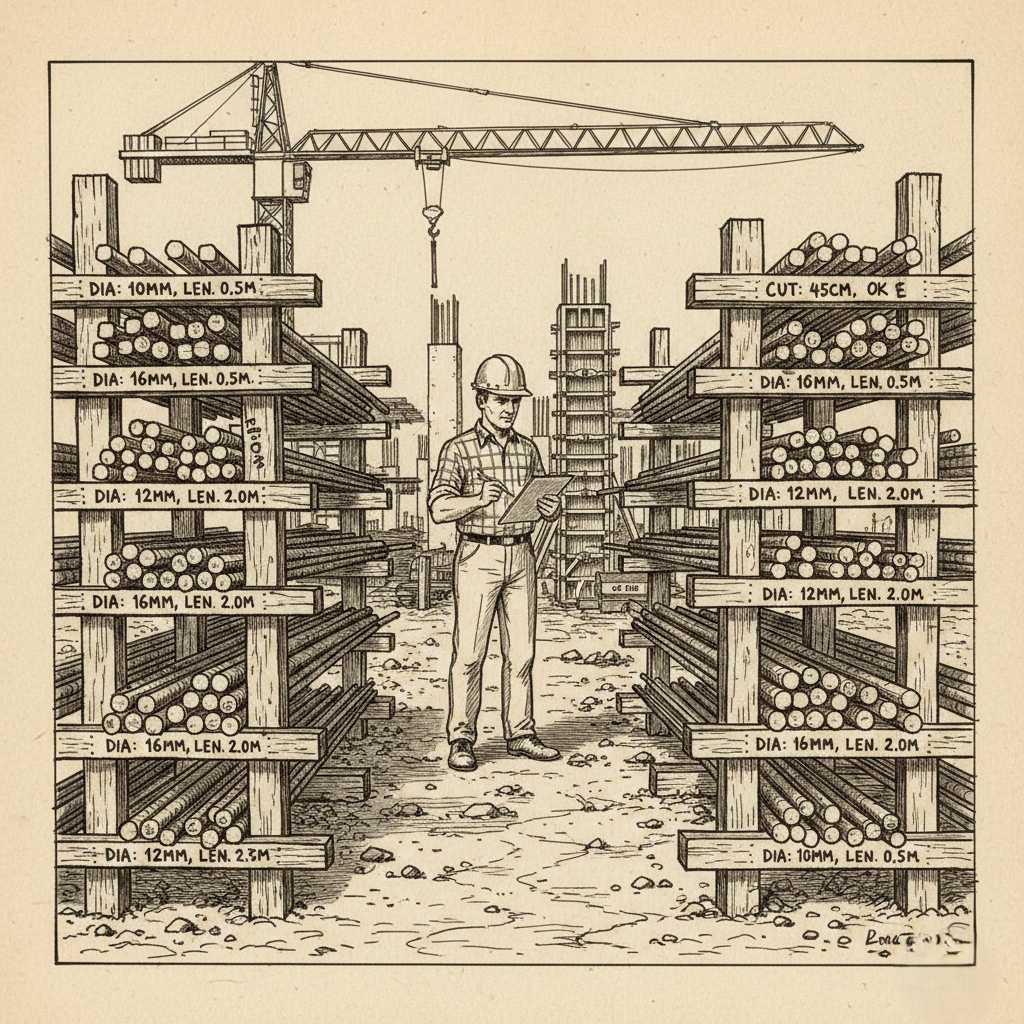

8.3 Establishing a Rebar Offcut Inventory System

8.3.1 Physical Storage Layout (Site Level)

Best practice is to store offcuts exactly like new stock, not as waste.

Recommended layout:

-

Separate racks by diameter

-

Colour-coded signage per diameter

-

Length zones (e.g. 1–2 m, 2–3 m, 3–4 m, 4 m+)

-

Raised racks to avoid ground moisture

-

Covered area for long-term storage

Example:

-

Yellow rack → 12 mm bars

-

Blue rack → 16 mm bars

-

Red rack → 20 mm bars

8.4 Minimum Reusable Length Criteria

The minimum reusable length should be defined at project start.

Typical industry practice:

| Bar Diameter (mm) | Minimum Reusable Length (m) |

|---|---|

| 10–12 | 0.8 |

| 16 | 1.0 |

| 20 | 1.2 |

| 25 | 1.5 |

| 32 | 2.0 |

These values come from:

-

Minimum anchorage length

-

Practical handling constraints

-

Common stirrup and dowel sizes

8.5 Inventory Recording (Simple but Effective)

8.5.1 Offcut Inventory Register (Blank Form)

Rebar Offcut Inventory Sheet

The form should include the following fields:

- Date

- Bar Dia (mm)

- Length (m)

- Quantity

- Total Length (m)

- Location

- Condition

- Intended Use

8.5.2 Weight Calculation

"Total Offcut Weight (kg)" = Total Length × Unit Weight

Where:

"Unit Weight (kg/m)" = d² / 162

Example (16 mm bar, 2.5 m length, 10 pieces):

Unit Weight = 16² / 162

= 1.58 kg/m

Total Length = 2.5 × 10 = 25 m

Total Weight = 25 × 1.58 = 39.5 kg

8.6 Integrating Offcuts into Future Cutting Plans

8.6.1 Principle

Offcuts should be treated as secondary stock lengths, not waste.

Hierarchy of use:

-

Offcuts first

-

Full stock bars second

-

New procurement last

8.6.2 Optimisation Including Offcuts

Modern optimisation (and GPT-assisted planning) can include offcuts as additional stock lengths.

Example Input to Optimiser:

-

Stock lengths:

-

12.0 m (new)

-

3.6 m (offcut)

-

2.4 m (offcut)

-

This approach reduces:

-

New bar consumption

-

Scrap accumulation

-

Storage congestion

8.7 Using GPT to Manage Offcut Inventory

8.7.1 What GPT Can Do

GPT can:

-

Analyse offcut inventory

-

Match offcuts to upcoming BBS requirements

-

Suggest reuse scenarios

-

Rank offcuts by priority

-

Estimate savings from reuse

8.7.2 Professional GPT Prompt – Offcut Reuse Planning

Use this prompt exactly:

You are a construction materials planning engineer.

I will provide a list of available rebar offcuts and upcoming reinforcement requirements.

Your task is to:

Match offcuts to required bar lengths where feasible

Identify which bars can be fully replaced using offcuts

Calculate steel weight and cost saved

Highlight offcuts that cannot be reused

Present results in a table suitable for Excel or Word

Offcut inventory:

16 mm bars:

3.6 m × 40

2.8 m × 30

1.5 m × 20

Upcoming requirements:

2.5 m × 50

3.4 m × 30

Steel cost = AUD 1,200 / ton

This enables planners to make data-driven reuse decisions, rather than relying on assumptions.

8.8 Cost Saving from Offcut Reuse – Example

Example Calculation

Reusable offcuts:

-

Total offcut length = 180 m

-

Diameter = 16 mm

-

Unit weight = 1.58 kg/m

Total Weight =

180 × 1.58 = 284.4 kg ≈ 0.284 t

Cost Saved =

0.284 × 1,200 = AUD 341

On a large project, cumulative reuse easily exceeds AUD 10,000–50,000.

8.9 Governance and Responsibility

Best practice assigns responsibility clearly:

-

Site Engineer: verifies suitability

-

Foreman: controls physical storage

-

Planner: integrates into cutting plans

-

QA/QC: approves reuse per spec

Without ownership, offcut systems fail.

8.10 Common Mistakes to Avoid

-

Mixing diameters

-

Ignoring rust protection

-

No length labelling

-

No minimum reuse rule

-

Treating offcuts as “free material”

-

Failing to include offcuts in planning