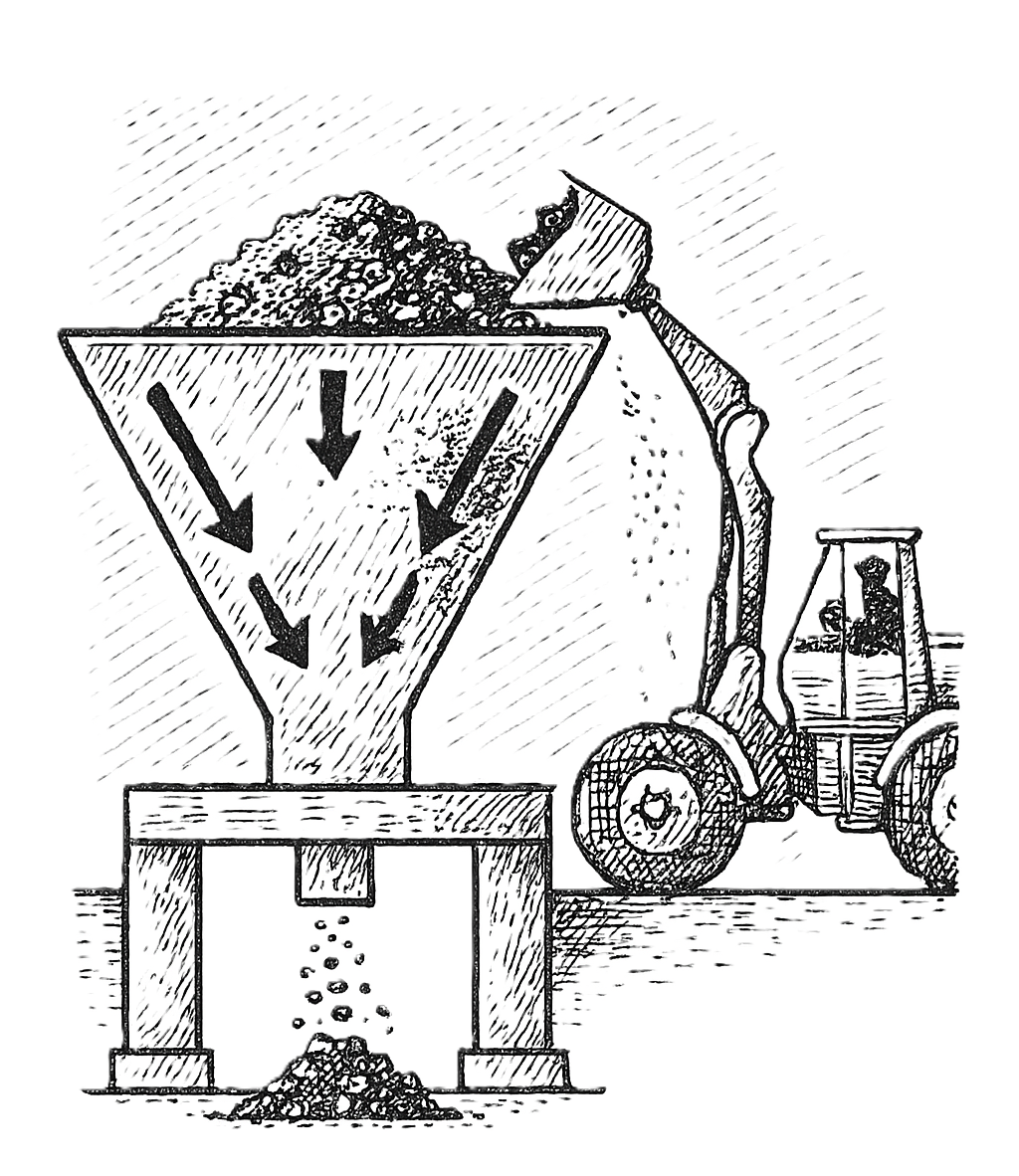

The Role of Hoppers and Bins in Bulk Material Handling

Dec 28, 2025Role of Hoppers and Bins in Bulk Solids Handling

1- Why Hoppers and Bins Matter

In mining and bulk solids processing plants, hoppers and bins are often perceived as passive elements—simple storage volumes positioned between active machines such as crushers, screens, conveyors, and mills. This perception is misleading. In reality, hoppers and bins are active control elements that strongly influence material flow, equipment performance, structural reliability, and operational safety.

Hoppers and bins perform several critical functions simultaneously:

-

They buffer upstream and downstream equipment.

-

They regulate the flow rate into feeders and process units.

-

They provide surge capacity during transient or upset conditions.

-

They act as stabilising elements in systems subject to variable feed rates.

-

In some cases, they perform partial blending or homogenisation of material.

For example, if a belt conveyor trips for a short duration, a correctly designed bin can maintain feed to downstream equipment, preventing unnecessary plant stoppages. Similarly, if a crusher experiences surge flow, a hopper can dampen these fluctuations and deliver a more uniform discharge to the next stage.

When hoppers and bins are poorly designed or incorrectly applied, the resulting problems propagate throughout the plant:

-

Feeders become starved or overloaded.

-

Throughput becomes unstable.

-

Operators are forced into unsafe manual intervention.

-

Structural components experience unexpected loads, fatigue, or failure.

Good hopper and bin design is, therefore, not merely a geometric exercise. It is a multidisciplinary engineering task that directly impacts plant availability, safety, maintenance costs, and production rates.

2- Typical Problems with Poor Hopper and Bin Design

A common mistake among inexperienced designers is to size bins purely by volume:

-

“We need 100 m³ of storage.”

-

“We have space for a 3 m diameter by 10 m high bin.”

Often, geometry is copied from previous projects without understanding the material properties or flow requirements that made the original design successful or unsuccessful.

2.1 No-Flow or Erratic Flow

The most common flow problems include:

-

Arching (bridging): A stable arch of material forms across the outlet, preventing discharge.

-

Ratholing: A flow channel develops above the outlet while material near the walls remains stagnant.

-

Stop–start flow: Material alternates between flowing and suddenly stopping, producing surges.

These phenomena cause:

-

Frequent downtime for clearing blockages.

-

Severe safety hazards exist when operators enter confined spaces.

-

Large fluctuations in feed rate to crushers, mills, and screens.

2.2 Segregation and Inconsistent Product

Even when flow appears acceptable, internal segregation may compromise process performance:

-

Fine particles migrate to the centre or walls.

-

Coarse particles discharge preferentially.

-

Moisture and chemical composition vary with time.

In bins, feeding mills, or acting as blending silos, this leads to:

-

Reduced grinding efficiency.

-

Variable moisture in downstream products.

-

Inconsistent metallurgical or chemical performance.

2.3 Structural Damage

Bulk solids impose loads fundamentally different from liquids:

-

Pressures are non-uniform and history-dependent.

-

Peak loads often occur during discharge rather than filling.

-

Eccentric flow generates asymmetric forces.

If these effects are ignored:

-

Flat walls may bulge or crack at welds.

-

Conical hoppers may buckle at the knuckle.

-

Supports may fail due to unexpected shear or bending.

Many plants follow a costly pattern: years of repairs and reinforcements, followed by full replacement at significantly higher cost than proper initial design.

3 A Practical Design Process

A robust hopper or bin design follows a disciplined sequence:

-

Define the material and duty

-

Material type (ore, coal, cement, concentrate)

-

Bulk density, moisture range, fines content

-

Required throughput (t/h)

-

Required storage capacity (t or m³)

-

Operating mode (continuous, batch, start/stop)

-

-

Select the desired flow pattern

-

Mass flow or funnel flow

-

Sensitivity to segregation

-

Reliability requirements

-

-

Choose hopper geometry

-

Conical, wedge, pyramidal, or hybrid

-

Hopper half-angle

-

Wall material and liners

-

Outlet shape and size

-

Interface with the feeder type

-

-

Estimate pressures and loads

-

Vertical and horizontal pressures

-

Loads during filling and discharge

-

Eccentric and transient load cases

-

-

Size plates and stiffeners

-

Shell thickness

-

Stiffener spacing and section

-

Local reinforcement at outlets and transitions

-

-

Verify access and maintainability

-

Inspection access

-

Safe clearing provisions

-

Liner replacement

-

Allowance for future modification

-

4 Basic Geometry and Terminology

4.1 Bins, Silos, and Hoppers

-

Bin or silo: Vertical storage section.

-

Hopper: Sloping section leading to the outlet.

Although often referred to collectively as “hoppers,” distinguishing these sections is critical for both flow and structural analysis.

4.2 Conical Hoppers

Defined by:

-

Top diameter: D₁

-

Outlet diameter: D₀

-

Hopper half-angle from vertical: θ

4.3 Wedge (Plane) Hoppers

A wedge hopper consists of:

-

Two sloping plane walls

-

Two vertical walls

-

A rectangular or slot outlet

Key dimensions:

-

Outlet width: B

-

Outlet length: L

These are commonly used above-belt and apron feeders.

4.4 Transition Pieces

Transitions between bin and hopper sections are structurally critical due to:

-

Rapid geometry change

-

Load concentration

-

Changes in stiffener layout

These regions require special attention to reinforcement.

Practical Hopper and Bin Design for Bulk Solids Handling

Book Overview

Practical Hopper and Bin Design for Bulk Solids Handling is a technical, application-focused reference aimed at engineers and practitioners working with bulk materials in mining, minerals processing, and industrial plants. The book provides a clear bridge between bulk solids theory and real-world design practice, with strong emphasis on avoiding flow problems such as arching, ratholing, segregation, and erratic discharge.

Length:

The book spans approximately 130 pages, structured to support both progressive learning and quick reference for design tasks

Primary Focus:

-

Design and operation of hoppers, bins, silos, and stockpiles

-

Mass flow vs funnel flow behaviour

-

Material properties affecting flow (bulk density, moisture, cohesion, particle size distribution)

-

Practical design methods, rules of thumb, and engineering judgement

-

Common failure modes and how to prevent them

Learning Outcomes:

After reading this book, the reader will be able to:

-

Understand how bulk material properties influence storage and discharge behaviour

-

Distinguish between different flow regimes and select appropriate hopper geometries

-

Apply practical design principles to prevent blockages and flow instabilities

-

Recognise the limitations of purely theoretical approaches and incorporate operational experience into design decisions

-

Communicate hopper and bin design intent clearly within multidisciplinary project teams

Target Audience:

-

Mechanical, civil, and process engineers

-

Mining and materials handling professionals

-

Plant designers and operators

-

Engineering students specialising in bulk solids handling

Overall Value:

Rather than being a purely academic text, this book serves as a hands-on engineering guide, grounded in industry experience. It is especially valuable for professionals responsible for the reliability, safety, and performance of bulk material handling systems.